Modify Furniture Embraces the Art of Prototyping and Lean Production in the Modern Era

Say goodbye to the days when product development was prohibitively costly, time consuming and inaccessible to most. Thanks to modern innovative processes and social channels, start-up companies like Modify Furniture can develop and produce their own line of modern luxury, sustainable products.

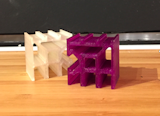

Possibly the greatest recent innovation for product development has been affordable rapid prototyping using additive technology. With the advent of more modestly priced 3d printers, inventors and designers now have the ability to model and refine multiple iterations of a product without the need for expensive and time-consuming specialty processes. The patent-pending aluminum framing system used to create the innovative Polychrome Series was developed by the Modify Furniture design team in just that way.

Affordable online freelance designer sites like freelancer.com have also helped companies like Modify find help with complex 3d modeling. Modify designer and furniture maker, Marci Klein explains, "I can delineate a consumer problem, imagine a solution, envision the design and put it down on paper. That’s when I turn to a freelancer. Turning my drawing into a readable file for prototyping and production is a skill that I prefer to leave to a professional trained in the field." It can take anywhere from 1-3 days to go from my imagination to a tangible object ready for evaluation and testing. Not bad timing in the world of product development."

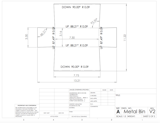

Additive technology with 3d printing is an instrumental tool during the development phase of many of Modify Furniture’s designs. Equally as important is the CNC router (computerized table router) in creating and testing new designs. The ability to convert a paper drawing to CAD, CAM, and then have the machine create that object in a period of hours has allowed the company to quickly and easily fine tune their designs and produce samples that can then be put out for customer feedback through in their showroom and photographed for comments on social channels.

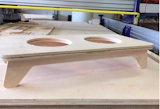

Their pop-up shop at the Broadway Market Co. in the heart of SOHO, Manhattan is the perfect crucible for these new designs. "While working at the showroom, it occurred to me one day how I've designed so many products for humans and have completely neglected the furry little creatures so many New Yorkers consider family members. How insensitive of me, I thought to myself"

One week later, Modify rolled out their first "Dog-Gone Deluxe" raised dog bowl prototype for customer feedback. Pooches of all sizes were invited to test the product while their ownersoffered feedback on the design. "More narrow, taller, eco-friendly, a splash of color were some comments that helped me refine the product." I’ve been asked to design a limited edition version for a local pet shop and had some preorder requests for the upcoming holidays. With the CNC router, the ability to create one or very small batches of a product for refining purposes can be instrumental for a company like Modify that sells directly to customers.

CNC routing technology is by no means considered affordable; high end production-models can be quite pricey. Luckily there are options available to help with this drawback. Community maker-spaces have sprouted up across the nation from the hobbyist/prototyping to production/independent designer level. Collaborative facilities like the New Lab at the Brooklyn Navy Yard are spaces where start-ups can access affordable prototype and production equipment that would otherwise make it impossible for designers to create.

The made-to-order, just in time process is another contemporary concept in today's manufacturing. This approach enables companies to offer a higher level of customization and the unique ability to foster real relationships between the maker and the customer. At the same time, this manufacturing method avoids overproduction and overstock. "I consider it a protective measure against foreign copycats. You can’t easily make one-of-a-kind custom pieces abroad and send them direct to individual customers. This my response to the mass-production, super-sized stores that focus on cheaper products, larger volumes, and fierce competition. Amazon already has that system optimized. My plan is to take Modify Furniture the other direction."

Published

Last Updated

Get the Dwell Newsletter

Be the first to see our latest home tours, design news, and more.